Innovation – the driver of true transformation

Innovation means using the knowledge we have to inspire change; to take a fresh look at our thinking to overcome barriers, enabling us to visualize all possibilities.

As part of Pathways to the Future, GSI members are always looking for innovations to help raise the performance of the salmon farming sector, but it is also important that innovation is not just an idea, but that we turn innovations into reality. Here are some examples of how GSI members have been doing just that.

1. Feed conversion ratio

Farm-raised salmon are carnivorous, and as such one part of their feed is sourced from wild pelagic fish species, which provide a diet rich in marine oils to ensure healthy growth. However, use of wild fish as an ingredient in aquaculture feed has received some negative associations due to its potential environmental impact. Given the expected growth of the farmed salmon industry, it is therefore imperative that the industry looks for alternative feed sources to reduce the dependency on wild stocks – which is where innovation comes in.

The feed conversion ratio (FCR), defined as the amount of feed needed to increase an animal’s bodyweight by one kilogram, is an important aspect of feed performance as it not only contributes to how efficient fish growth is, but also is an important measure of sustainability and a metric for the responsible use of resources. As members of the GSI, we therefore use this ratio to demonstrate the efficiency of turning feed into protein, and the lower it is, the more efficient salmon growth is.

Innovation in FCR is not just about looking at the feed ingredients, but looking at genetics, the environment (temperature, oxygen and light) and also the fish husbandry. Together with improvements in the feed ingredients profile, the salmon farming industry has reduced its FCR from 1.9:1 in the 1980s to 1.15:1 on average today, making it one of the most efficient sources of protein available.

“In the early days of aquaculture, farmers would feed raw fish directly to their fish, which created a lot of water pollution because the fish could not eat everything, so lots of nutrients were lost in the water. BioMar was one of the first companies to create a pelletized feed that significantly reduced the FCR and created a stable supply of feed. Since then, BioMar has adopted some very interesting feed production technology that has helped to create a better, more efficient feed pellet. Engineering feats such as advanced extrusion technology and vacuum coating made it possible to create a feed pellet that retained more nutrients, which makes for a better FCR.”

Niels Alsted, VP Business Relations, BioMar Group (GSI Associate Member)

To learn more on the developments in FCR, please see this report from an FAO and GSI co-hosted FCR workshop in Costa Rica in 2015.

2. Feed ingredients

As mentioned, feed ingredients play an important role in the efficiency of salmon farming, but they also play an important role in providing the farmed salmon with all the protein and essential nutrients they need for optimal health and growth. To help conserve resources, the industry has been looking for innovative alternative ingredients that allow for the inclusion of fatty omega-3 acids (EPA and DHA), without relying solely on fish oil. One of those innovative alternatives is the use of novel oils.

Here, Einar Wathne, Seafood Leader of Cargill, provides an update on how Cargill has been supporting the development of these novel resources.

Cargill has worked closely with a supplier to develop a source of algal oils, which we have included in the diets of two key customers since early 2018. The algal oil will supply 20% of the EPA and DHA in the feed, saving 330 tonnes of fish oil. This has increased the EPA and DHA in the final fillet, boosting the benefits of eating farm-raised salmon.

Cargill is also continuing its research of canola, genetically modified to produce EPA and DHA. Trials in Chile on Atlantic salmon show that the fish store EPA and DHA from these oils as they would from fish oil. Further tests are planned before the commercial licenses for this material are expected in 2020.

We are also continuing our exploration of Calysta's FeedKind protein material, a sustainable ingredient made from fermentation of methane gas. It has been tested in a variety of feeds under different conditions, but is not yet available commercially.

In addition, small volumes of insect meal are becoming available and permitted to use after changes in EU and Canadian laws. We plan to carry out some customer trials in 2018, and in the meantime encourage collaboration through the value chain to make this novel raw material viable.

New and innovative raw materials are key to the future of aquaculture, but they face the same economic challenges as any start-up. It takes time and investment before they can compete with established raw materials such as fishmeal, fish oil and soy. So, what will it take for novel ingredients to become a true factor in nutrient supplies for fish feed?

In Cargill, we believe in active engagement with various suppliers, as this has already brought new and more sustainable raw materials into feed. We also think along the lines of a value-chain partnership where each player is willing to commit, compromise and share the costs of preparing for the future.

3. Technological advancements

Fish farming has come a long way since it began, when it was simply pens in the ocean. Today, salmon aquaculture is one of the most technologically advanced farming systems in the world. From the design of the pens, to their location, to how the fish are fed and handled – salmon aquaculture is a science based on decades of knowledge and precision, and the industry continues to build on experience to further refine the farming process for the benefit of the fish, the environment and the consumer. One of the most exciting developments currently underway is the Cermaq iFarm technology.

Here, Harald Takle, Technology Research Director of GSI Member Cermaq, tells us more.

iFarm – providing a health journal for each fish

iFarm is a technology focusing on farmed fish health and welfare, and recognizing fish as individuals – it thus has the potential to revolutionize fish farming.

A fish thrives when it is healthy, has good nutrition, has sufficient living space of the right quality and is left alone. This is not very different from other forms of husbandry.

In today’s salmon farms we manage all the fish in a pen the same way. This means that if some fish in a pen have sea lice, all fish are treated. The fish are stressed by the treatment and we treat far too many fish.

iFarm uses digital recognition of the fish. This allows us to monitor factors including growth, sea lice, disease, lesions and other aspects that affect the health and welfare of the individual fish.

In addition, it is possible to separate healthy fish from the fish that need treatment, for example against sea lice. Thus, the extent of sea lice treatment will be dramatically reduced. In addition, mortalities in production will be reduced by 50–75%.

Introducing an iFarm sensor in a fish farm will reduce the environmental footprint of the farm while ensuring welfare for each fish. The technology can be used in net pens as well as in closed systems.

The digitalization delivered by iFarm will also provide authorities with real-time data of the status of all the fish and will improve and simplify the governance of fish farming.

According to Cermaq, the development of iFarm requires six years with comprehensive scope of fish.

4. Fish health

Fish health continues to be the number one priority for GSI members. However, like any animal, farm-raised salmon are also susceptible to illness and disease, and as farmers it is our responsibility to use our best knowledge to support optimal fish health and prevent illness as best possible. Whether this is through improving husbandry practices, working with the latest R&D for medicinal support, or by utilizing the latest technologies to help us improve fish health and fish welfare, we are always looking to innovate our practices to keep our farmed fish as healthy as possible.

Here we see how Peter Bender, Managing Director and CEO of GSI Member Huon Aquaculture, has introduced new well-boat designs to improve management of fish health on its farms.

Amoebic gill disease (AGD) has been a significant issue in the Tasmanian Atlantic salmon industry since it started in 1985. Although mortality due to AGD is minimal, the financial and logistical cost of regular freshwater treatments is substantial. Farmed fish growth can also be significantly impacted if handling procedures and treatments are not low-stress. Treatment methods have evolved at Huon Aquaculture Group (Huon) from simply moving fish into floating liners of freshwater which removes the disease from the fish, to current procedures utilizing world-leading innovative well-boat technology. Modern well-boats can bathe large numbers of fish in an effective, efficient and low-stress way. This is critical in enabling Huon to farm in offshore high-energy sites, which experience significant wave heights over 11 metres.

Huon’s current well-boat (Ronja Huon) leased from Solvtrans is 76m in length, holds 3,000m3 and can pump 300 tonnes biomass per hour. However, Huon’s new well-boat (Ronja Storm) currently being built and due in Tasmania late 2019 is 116m in length, will hold a total of 13,000m3 and have a movement capacity of 700 tonnes biomass per hour. The Ronja Storm will have the capacity to treat an entire 240m circumference pen of farmed fish (i.e. 700 tonnes biomass) in one treatment. An on-board reverse osmosis plant will be able to produce 700 m3/hr at 0.3 parts per thousand. salinity using ultrafiltration technology. The boat will also have the latest technology for chilling water at 1°C/hr, oxygen generation, CO2 stripping, faster cleaning and disinfection systems, counting and biomass assessment.

This technology allows us to treat the fish in the quickest and most stress-free environment to keep the salmon healthy and happy. As part of the GSI Biosecurity taskforce, we have shared this development to help other members utilize the knowledge for their salmon farming operations.

5. Circular economy

The circular economy aims to redefine growth, and instead focus on using resources for as long as possible, to extract the maximum value from them and reduce the amount of waste we produce. With this in mind, it provides an opportunity to rethink current production cycles and find ways to re-use or extend the life of products that we previously had not considered.

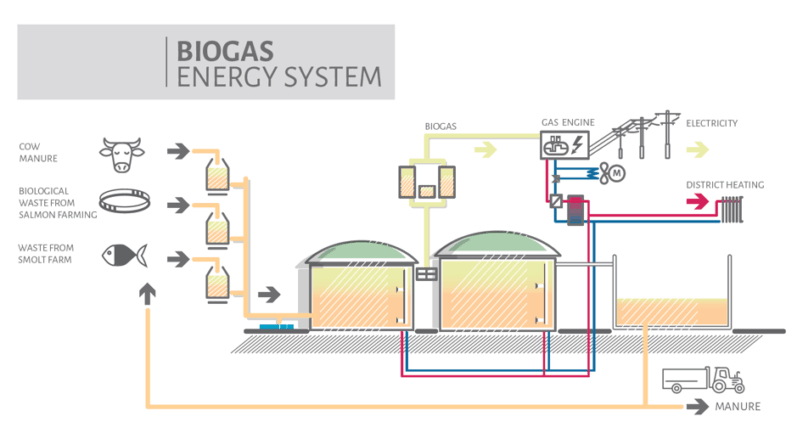

One way this is possible in the farmed salmon industry is to collect what we see as waste, and turn this into energy.

Here, GSI Member Bakkafrost’s CEO Regin Jacobsen discusses how innovation is helping create a completely new industry through the circular economy.

Bakkafrost has employed a systematic approach to optimizing raw material use and minimizing waste since the company started 50 years ago. We have an ambitious investment strategy focussed on efficient growth to meet the growing demand for sustainably produced protein. This includes advancing circular solutions that reduce waste, reduce and avoid CO2 emissions, and stimulate sustainability through other industries.

In March 2018, Bakkafrost made a commitment to invest in the Faroe Island’s first biogas plant, which when in operation, will have the capacity to convert up to 90,000–100,000 tonnes annually of all waste from salmon and dairy farms. With the current input predicted, this will provide enough renewable heat for 400 homes and electricity for 1,900 homes. This is projected to save 11,000 tonnes of CO2 emissions and produce 40,000–45,000 tonnes of natural liquid fertilizer annually.

The renewable energy produced from waste will feed in to the national grid, contributing to the Faroe Island’s national target to have 100% electricity from renewable sources by 2030, which in October 2018 was already at approximately 75%.

Bakkafrost’s approach to the circular economy has received recognition at international sustainability awards.

More information on Bakkafrost’s two-year sustainability plan, including commitments to continue to increase transparency on how the company is addressing industry-wide sustainability issues, can be found in its 2017 Healthy Living Sustainability Report.

Innovation is never a tick box

These are just a flavour of some of the innovations taking place across GSI member farms, but we expect to see many more over the coming years. As GSI members, we believe that greater innovation, and greater diffusion of innovation, will play an important role in realizing our goals much faster and at a greater scale than would otherwise be possible.